We Shape and Enhance Your Idea

Every accessory starts from an intuition. We transform it into a tangible, striking, and functional piece, perfectly integrated into your collection.

Step 1

Technical Analysis of Your Project

Share your idea with us: our technical office will analyze it to transform it into a functional, durable, and well-designed metal accessory.

Share Your Idea

Step 2

Prototyping in 72 Hours

After the design is approved, we create a prototype within 72 hours: you can evaluate it firsthand and decide whether to proceed with production.

Share Your IdeaStep 3

Material Selection

We guide you in choosing the most suitable material: Zamak for large-scale, high-quality production; rubberized Zamak for complex items and medium series; brass for prototypes or small quantities.

Each option is evaluated together to ensure both aesthetic appeal and functionality.

Share Your Idea

Step 4

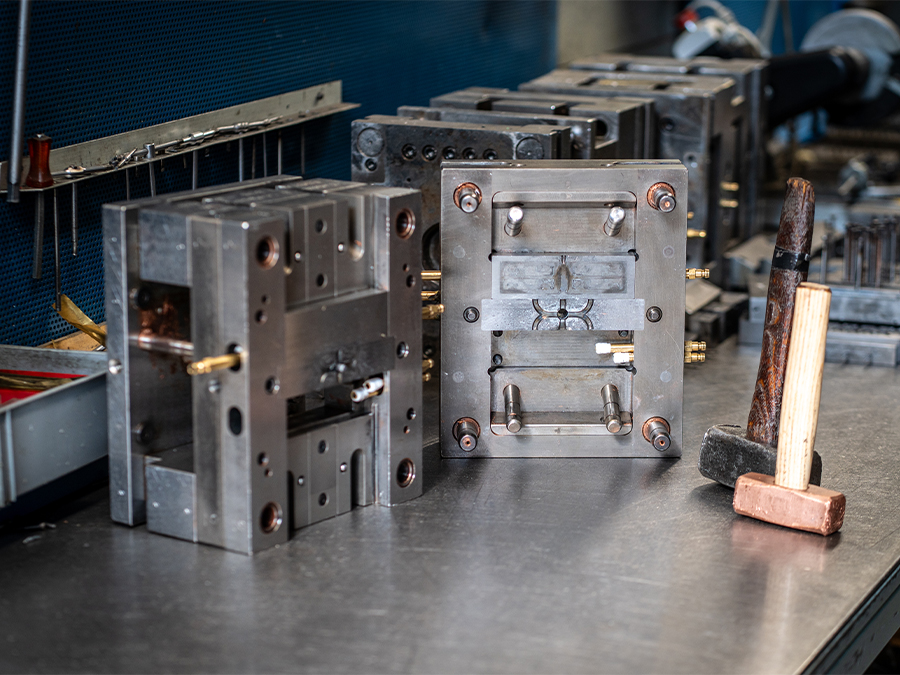

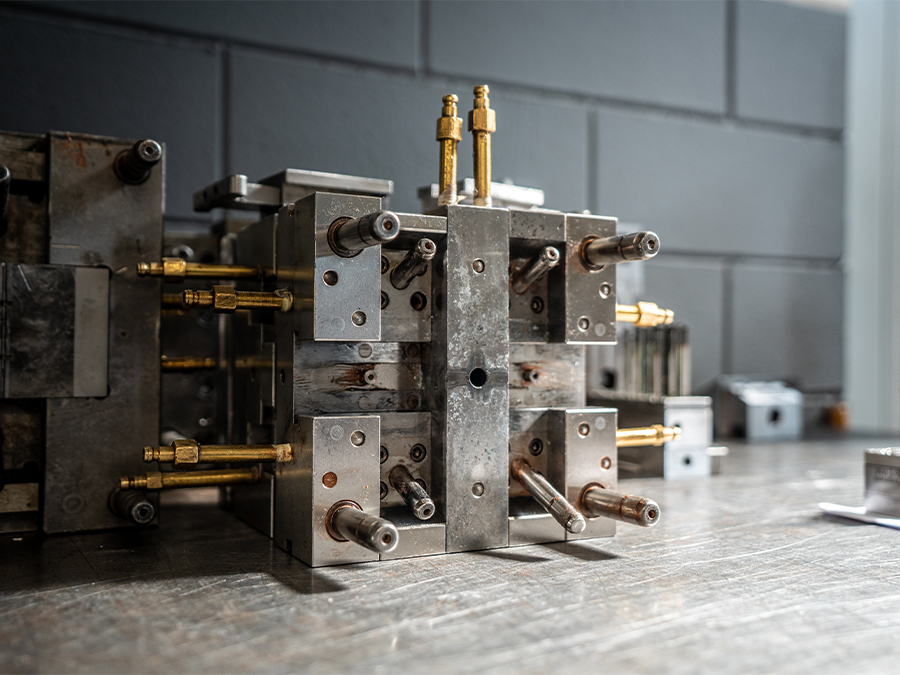

Mold Production

We create custom molds starting from optimized inserts for our presses.

Specially designed extraction systems minimize surface marks, reducing the need for touch-ups and avoiding delays in delivery times.

Each mold is coded and stored in a vertical warehouse with digital management, ensuring quick retrieval and optimal preservation.

Explore the Production DepartmentStep 5

CNC Molding

We perform serial molding using advanced machines and robotic arms, ensuring consistent precision, speed, and integrated quality control in every cycle.

Explore the Production Department

Step 6

Finishing

We handle sandblasting, polishing, and laser engraving in-house, respecting brand specifications. Through selected partners, we carry out electroplating, enameling, painting, and digital printing, customizing every detail while ensuring top quality.

Share Your IdeaStep 7

Stock and Reordering

We store raw items in labeled vertical warehouses for quick reorders and fast retrieval via management software, ensuring timely responses and efficient production.

Share Your Idea